Mastering Flat Pattern Creation in SolidWorks: A Comprehensive Guide

Introduction: Creating flat patterns in SolidWorks is an essential skill for sheet metal designers and engineers, enabling them to accurately unfold and document sheet metal parts for manufacturing. Whether you’re designing complex enclosures, brackets, or assemblies, SolidWorks provides powerful tools for generating precise flat patterns that facilitate fabrication and assembly processes. In this comprehensive guide, we’ll explore the intricacies of creating flat patterns in SolidWorks, covering fundamental concepts, essential techniques, and advanced strategies to help you master this crucial aspect of sheet metal design.

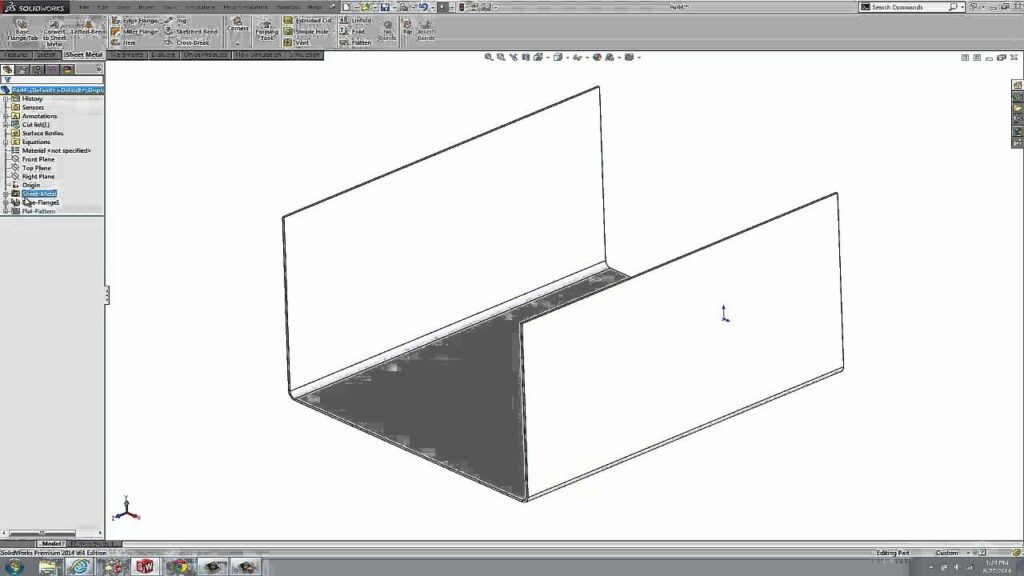

Understanding Flat Patterns in SolidWorks: Flat patterns represent the flattened, 2D representations of sheet metal parts before they are formed and assembled. SolidWorks generates flat patterns by unfolding the 3D geometry of sheet metal parts along bend lines and edges, preserving the correct dimensions, features, and cutouts. Flat patterns serve as blueprints for manufacturing, providing fabricators with the information needed to laser cut, punch, bend, and form sheet metal parts accurately. Before delving into the specifics of creating flat patterns, it’s essential to grasp some foundational concepts:

- Bend Allowance:

- Bend allowance is the amount of material elongation or stretching required to accommodate bending without distortion or deformation. SolidWorks calculates bend allowance based on material thickness, bend radius, and bend angle, ensuring accurate flat pattern dimensions.

- Bend Deduction:

- Bend deduction is the length of material consumed by bending, accounting for the stretching and compression effects of the bend radius. SolidWorks calculates bend deduction to determine the correct length of the bend line in the flat pattern, ensuring accurate part dimensions and bend positions.

- K-Factor:

- K-factor is a coefficient that represents the ratio of bend allowance to material thickness, used to calculate the location of the neutral axis during bending. SolidWorks allows users to specify K-factor values based on material type, bend radius, and bending method to ensure accurate flat pattern development.

Creating Flat Patterns in SolidWorks: Let’s explore the essential steps for creating flat patterns in SolidWorks:

- Model the Sheet Metal Part:

- Begin by modeling the sheet metal part in SolidWorks using sheet metal features such as flanges, bends, tabs, and reliefs. Define the part geometry, dimensions, and features according to design requirements and manufacturing constraints.

- Apply Material and Thickness:

- Apply the appropriate material and thickness to the sheet metal part to define its physical properties and manufacturing characteristics. Specify material properties such as density, yield strength, and elastic modulus to accurately simulate material behavior during bending and forming operations.

- Insert Bend Features:

- Insert bend features into the sheet metal part to define bend lines, bend angles, and bend radii. Use SolidWorks bend tools to specify bend parameters, including bend direction, bend relief type, and bend allowance calculation method.

- Flatten the Part:

- Flatten the sheet metal part to generate its flat pattern representation. Use SolidWorks flatten tools to unfold the part geometry along bend lines and edges, preserving feature dimensions and cutouts accurately.

- Verify Flat Pattern:

- Verify the accuracy of the flat pattern by reviewing dimensions, bend positions, and feature alignments. Use SolidWorks measurement tools to compare flat pattern dimensions with design specifications and manufacturing tolerances.

- Add Manufacturing Features:

- Add manufacturing features such as punch holes, laser cutouts, and bend lines to the flat pattern to facilitate fabrication processes. Use SolidWorks sketching and annotation tools to create machining features and annotations that guide fabrication and assembly.

- Document and Detail:

- Document the flat pattern using SolidWorks drawing tools to create manufacturing drawings, assembly drawings, and part specifications. Include dimensions, tolerances, annotations, and geometric tolerancing information to communicate flat pattern geometry accurately.

Advanced Flat Pattern Techniques: In addition to basic flat pattern creation tools, SolidWorks offers advanced techniques to enhance flat pattern development:

- Bend Table:

- Use bend tables in SolidWorks to define custom bend allowance and bend deduction values for specific material types, thicknesses, and bend radii. Bend tables provide flexibility and accuracy in calculating flat pattern dimensions for a wide range of sheet metal parts.

- Bend Compensation:

- Apply bend compensation techniques to adjust flat pattern dimensions and feature positions to account for material springback and bending variations. SolidWorks allows users to apply bend compensation factors and corrections to ensure accurate part geometry and fit-up during assembly.

- Export and Nesting:

- Export flat patterns from SolidWorks to industry-standard file formats such as DXF or DWG for fabrication and laser cutting. Use nesting software to arrange flat patterns on sheet metal stock efficiently, minimizing material waste and optimizing production efficiency.

Best Practices for Flat Pattern Creation: To maximize the effectiveness and efficiency of flat pattern creation in SolidWorks, consider the following best practices:

- Design for Manufacturability:

- Design sheet metal parts with manufacturability in mind, considering factors such as material thickness, bend radius, and tooling capabilities. Avoid sharp corners, tight bends, and complex geometries that may pose challenges during fabrication.

- Verify Accuracy:

- Verify the accuracy of flat patterns using SolidWorks simulation and validation tools to ensure that dimensions, bend positions, and feature alignments meet design specifications and manufacturing tolerances.

- Collaborate with Fabricators:

- Collaborate with sheet metal fabricators and manufacturers early in the design process to ensure that flat patterns are feasible, cost-effective, and compatible with fabrication processes. Consider input from fabricators regarding material selection, bend allowances, and assembly methods.

- Document Design Intent:

- Document flat pattern design intent clearly and comprehensively using SolidWorks drawing annotations and notes. Provide detailed instructions, dimensions, and tolerances to guide fabrication, assembly, and quality control processes effectively.

Conclusion: Creating flat patterns in SolidWorks is a critical aspect of sheet metal design, enabling designers and engineers to translate 3D models into accurate and manufacturable 2D representations for fabrication. By mastering flat pattern creation techniques and adhering to best practices, you can streamline the design process, optimize part performance, and facilitate efficient fabrication and assembly. Whether you’re a novice or an experienced SolidWorks user, understanding the fundamentals of flat pattern creation and exploring advanced techniques will elevate your sheet metal design skills and enable you to create innovative and high-quality parts with confidence.