Mastering Material Application in SolidWorks: A Comprehensive Guide

Introduction: SolidWorks, a leading computer-aided design (CAD) software, offers powerful tools for creating realistic 3D models with lifelike material appearances. Applying materials to models in SolidWorks allows designers and engineers to convey visual properties such as color, texture, reflectivity, and transparency, enhancing the realism and aesthetic appeal of their designs. In this comprehensive guide, we’ll explore the intricacies of applying materials to models in SolidWorks, covering fundamental concepts, essential techniques, and advanced strategies to help you master this crucial aspect of design visualization.

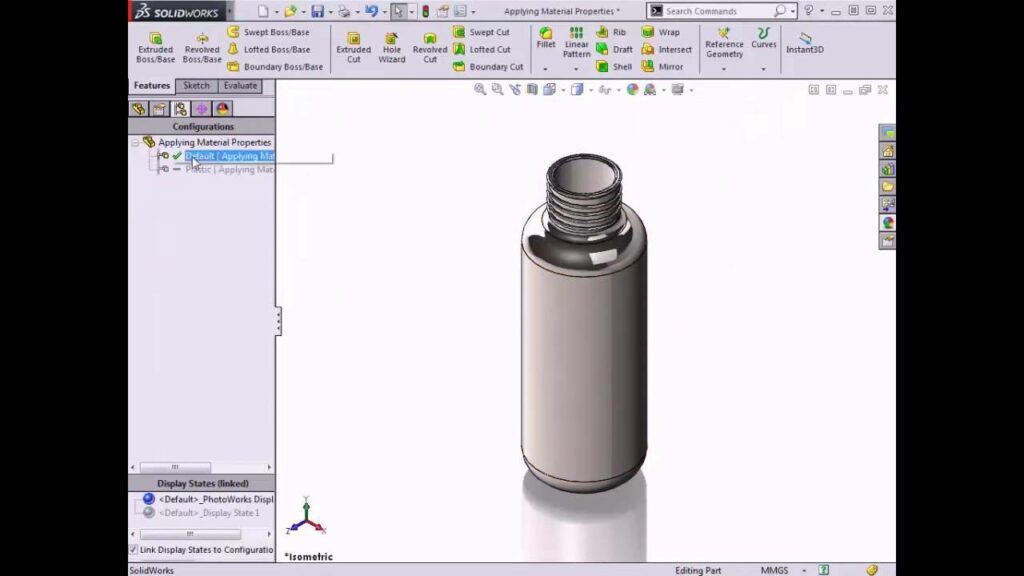

Understanding Material Application in SolidWorks: Material application in SolidWorks involves assigning visual properties to surfaces and components within a 3D model to simulate real-world materials accurately. By selecting appropriate materials and adjusting material properties, users can achieve lifelike renderings and visualizations that accurately represent the appearance and behavior of physical objects. Before delving into material application techniques, it’s essential to grasp some foundational concepts:

- Material Properties:

- Materials in SolidWorks define the visual appearance and surface properties of model components, including color, reflectivity, roughness, transparency, and texture. Each material is characterized by a set of properties that determine how it interacts with light and other materials in the scene.

- Material Library:

- SolidWorks provides a comprehensive library of predefined materials, including metals, plastics, glass, ceramics, and organic materials. The material library offers a wide range of options for simulating different material types, finishes, and appearances, saving users time and effort in material selection and configuration.

- Custom Materials:

- In addition to predefined materials, SolidWorks allows users to create custom materials with specific visual properties and characteristics. Users can define custom material properties such as color, texture, reflectivity, and transparency, as well as advanced properties such as anisotropy and subsurface scattering, to achieve desired visual effects.

Applying Materials to Models in SolidWorks: Let’s explore the essential steps for applying materials to models in SolidWorks:

- Select the Model:

- Begin by selecting the model or component to which you want to apply a material. Use SolidWorks assembly or part modeling tools to access and modify the geometry and surfaces of the model as needed.

- Open the Appearance PropertyManager:

- Open the Appearance PropertyManager by clicking on the “Edit Appearance” button in the CommandManager or by right-clicking on the model and selecting “Edit Appearance” from the context menu. The Appearance PropertyManager allows users to apply and modify materials, textures, and visual properties for selected model components.

- Choose a Material:

- Choose a material from the SolidWorks material library or create a custom material with specific visual properties. Browse through material categories such as metals, plastics, glass, ceramics, and paints to find the desired material type and finish for the model component.

- Apply the Material:

- Apply the selected material to the model component by dragging and dropping it onto the desired surfaces or faces in the graphics area. Alternatively, use the “Assign Material” tool in the Appearance PropertyManager to apply the material to selected faces or bodies explicitly.

- Adjust Material Properties:

- Adjust material properties such as color, texture, reflectivity, roughness, transparency, and bump mapping to achieve the desired visual appearance and surface characteristics. Use sliders, color pickers, and numerical inputs to fine-tune material properties and achieve realistic rendering effects.

- Preview and Evaluate:

- Preview the applied material in the graphics area to evaluate its visual appearance and compatibility with the model. Use real-time rendering tools such as SolidWorks Visualize or PhotoView 360 to visualize the model with applied materials in various lighting conditions and environments.

- Save and Apply:

- Save the applied material settings as part of the model configuration or appearance library for future use. Apply materials consistently across multiple model components or assemblies to maintain visual coherence and consistency in design presentations.

Advanced Material Application Techniques: In addition to basic material application tools, SolidWorks offers advanced techniques to enhance material realism and visual fidelity:

- Texture Mapping and UV Mapping:

- Use texture mapping and UV mapping techniques to apply textures and patterns to model surfaces accurately. SolidWorks provides tools for mapping texture coordinates onto model surfaces, allowing for precise control over texture placement, scaling, and orientation.

- Advanced Material Properties:

- Explore advanced material properties such as anisotropy, subsurface scattering, iridescence, and translucency to create highly realistic material appearances. Adjust material properties such as specular highlights, fresnel effects, and dispersion to simulate complex light interactions accurately.

- Material Mapping and Projections:

- Apply material mappings and projections to model surfaces to control how materials are applied and distributed across geometry. Use planar, cylindrical, spherical, or box mappings to project materials onto curved or irregular surfaces accurately.

Best Practices for Material Application: To maximize the effectiveness and visual impact of material application in SolidWorks, consider the following best practices:

- Understand Material Properties:

- Familiarize yourself with material properties and characteristics to choose appropriate materials for your model components. Consider factors such as material type, finish, reflectivity, and transparency when selecting materials for specific applications.

- Use Real-World References:

- Refer to real-world references such as material samples, photographs, and physical prototypes to guide material selection and configuration. Match material appearances and properties to real-world counterparts to achieve authenticity and realism in renderings.

- Experiment and Iterate:

- Experiment with different materials, textures, and visual properties to explore creative possibilities and achieve desired visual effects. Iterate on material application by refining material settings, adjusting lighting conditions, and evaluating rendering results until you achieve the desired level of realism and aesthetic appeal.

- Consider Context and Environment:

- Consider the context and environment in which the model will be presented when applying materials. Adapt material selections and configurations to suit specific lighting conditions, viewing angles, and presentation formats to enhance visual impact and relevance.

Conclusion: Material application in SolidWorks is a critical aspect of design visualization, enabling designers and engineers to create realistic and visually compelling representations of their 3D models. By mastering material application techniques and adhering to best practices, you can enhance the realism, aesthetic appeal, and communicative power of your designs effectively. Whether you’re a novice or an experienced SolidWorks user, understanding the principles of material application and exploring advanced techniques will elevate your design visualization skills and enable you to create stunning visual presentations efficiently.